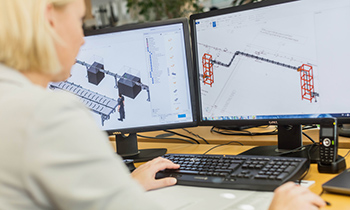

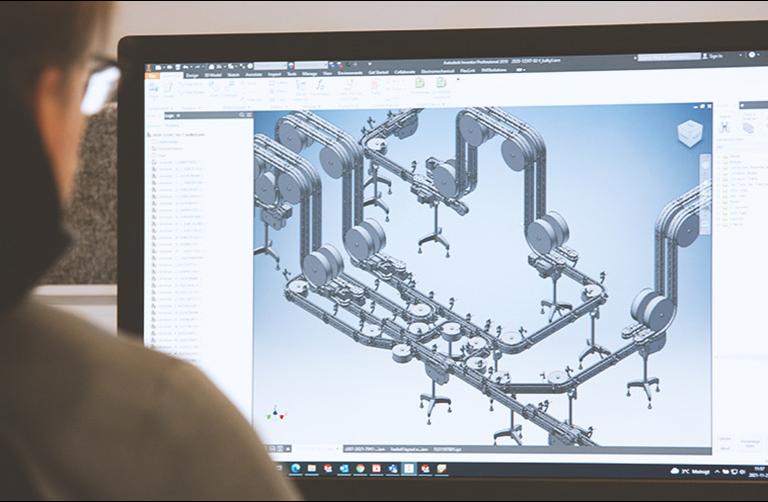

Combine multiple lines to consolidate production flows

Merging conveyors can be used to consolidate product flow from multiple infeed lines, and these conveyors can work in different ways. The right kind of merge solution for your business depends on your specific application along with product characteristics and production setup.

FlexLink’s technology for dynamic distribution and balancing of products delivers a high throughput in a continuous motion flow. It brings several benefits for your production line:

- Dynamic operation facilitating compact layouts

- Products are individually metered for optimal line balancing

- On-the-fly distribution, stops for shifting avoided

- No back-log requirements, no divert slugs

- No clamping or accumulation and easy change overs

- Flexible and easy change over